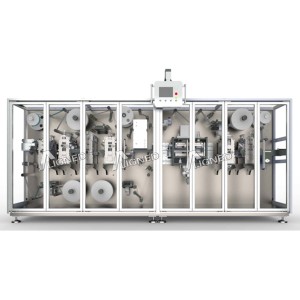

TPT-200 Transdermal Patch Packaging Machine

Product Description

Transdermal patch packaging machine is equipped with a high-precision circular knife die-cutting system and a reciprocating heat sealing system to ensure product quality and consistency. The workflow of this equipment includes steps such as material deviation, cutting easy-tear lines, die-cutting backing, slicing, visual inspection, printing batch numbers, four-side sealing, cutting, rejecting and packaging finished product transportation, realizing a fully automated production process. The whole machine adopts a motion control system with fast response and smooth operation. It is also equipped with a human-machine interface for easy operation.

Features

1. Transdermal patch packaging machine use imported servo motors, motion controllers, and human-machine interfaces, which are easy to operate and have stable performance.

2. Touch screen control, easy to adjust operating parameters, input product size, automatically configure the conveying length.

3. The temperatures of the upper and lower molds are independently controlled to more effectively ensure the quality of heat sealing.

4. Transdermal patch packaging machine use circular knife die-cutting system increases the die-cutting speed and ensures product size stability.

5. Continuous reciprocating heat sealing system improves heat sealing efficiency and effectively ensures production capacity.

Detailed description

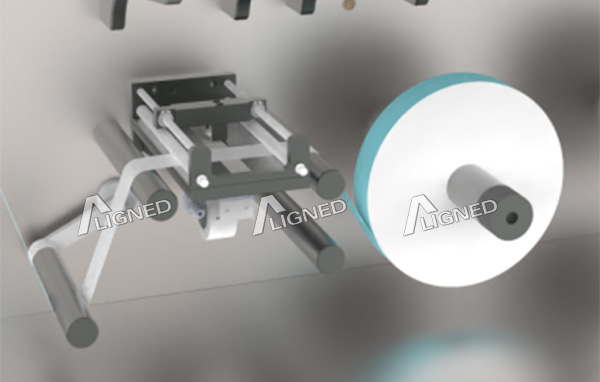

Rewinding and unwinding part

1. Use an air shaft to load film rolls

2. The tension roller controls the unwinding speed to ensure the tightness of the material film.

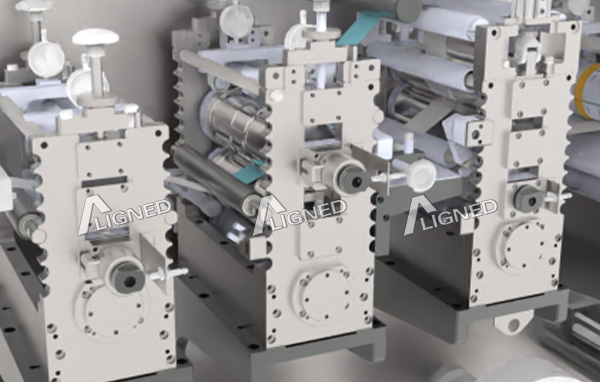

Round knife die cutting system

1. Servo controls the movement of the knife roller, and the feeding length is accurate;

2. Using motion controller, each workstation operates with precise coordination;

3. The knife roller is made of D2 imported mold steel, which has a long service life;

4. The frame structure is made of 2Cr13 material and complies with GMP requirements;

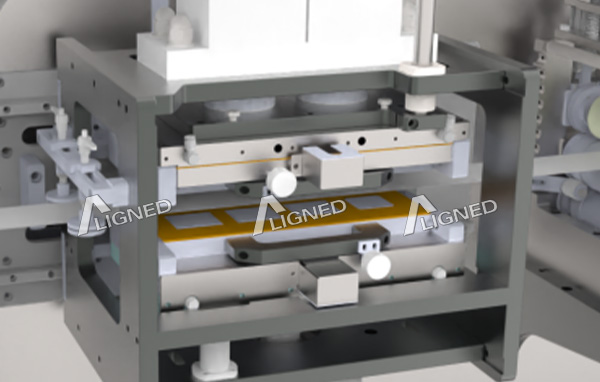

Reciprocating heat sealing system

1. It adopts servo control and reciprocating heat sealing to synchronize the heat sealing and feeding speed, greatly improving the machine operating speed.

2. The thermoforming mold can be replaced according to different product specifications;

3. Using imported cylinder drive, longer service life;

4. The temperatures of the upper and lower molds are independently controlled to ensure the heat sealing effect;

Technical Parameters

| Model | TPT200 transdermal patch packaging machine |

| Maximum packaging size | 200mmX200mm |

| Production speed | 100-150 packages/minute |

| Total power | 18kw |

| Air pressure | 0.5-0.7Mpa |

| Power supply | AC 380V 50HZ |

| Machine weight | 4000kg |

| Machine size | 4380mm X 1005mm X 2250mm |