OEM/ODM Factory Emulsifying Mixing Tank – ZRX Series Vacuum Emulsifying Mixer Machine – Aligned

OEM/ODM Factory Emulsifying Mixing Tank – ZRX Series Vacuum Emulsifying Mixer Machine – Aligned Detail:

Feature

1. The material of contacted part is SUS316L stainless steel, inside and outside of the equipment are with mirror polishing and get to GMP standard.

2. All pipelines and parameter are controlled automaticlly. And the electric appliance which are imported from foreign country, like Siemens, Schneider and so on.

3. Emulsifying tank is with CIP cleaning system, it make the cleaning to be easy and effective.

4. Emulsifying tank adopts tertiary agitating system, and during the emulsification, the whole processing is under a vacuum environment, so it not only can eliminate spume which created in the emulsification processing, but also can avoid the unnecessary pollution.

5. The homogenizer adopts the most advanced technology, it can get a ideal emulsifying effect. The speed of high emulsification is 0-3500r/min, and the speed of low mixing is 0-65r/min.

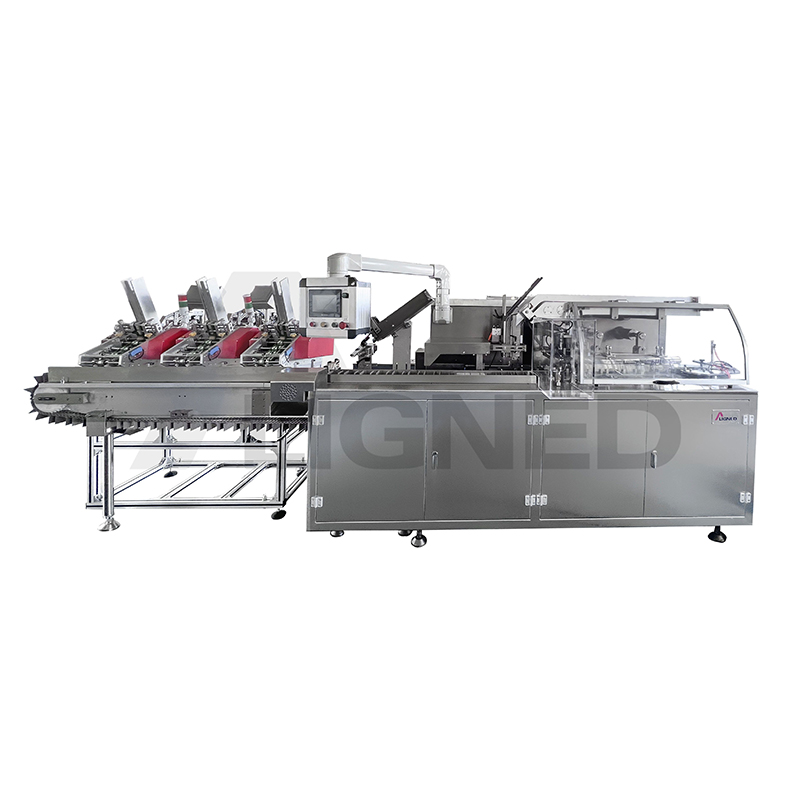

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for OEM/ODM Factory Emulsifying Mixing Tank – ZRX Series Vacuum Emulsifying Mixer Machine – Aligned , The product will supply to all over the world, such as: Cannes, Rotterdam, French, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.