Low price for Emulsifier Mixer Machine - OZM-120 oral dissolving film making machine (lab type) – Aligned

Low price for Emulsifier Mixer Machine - OZM-120 oral dissolving film making machine (lab type) – Aligned Detail:

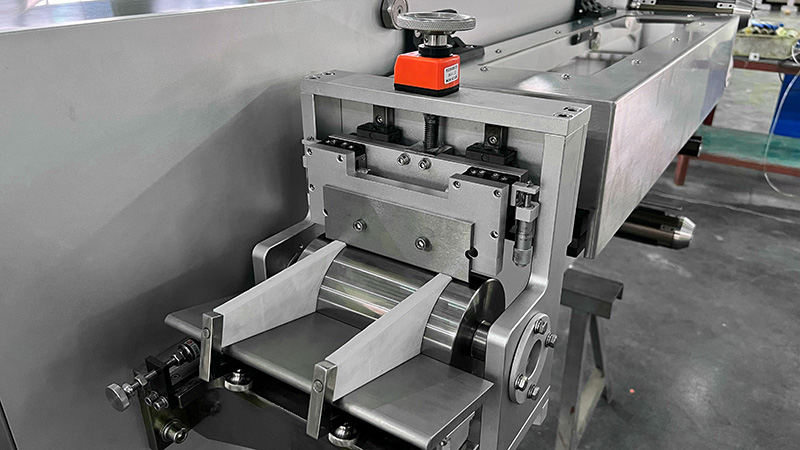

Sample diagram

Description

The oral dissolving film making machine (lab type) is a special equipment that evenly spreads the liquid material on the bottom film to make a thinner film material, and can be equipped with functions such as lamination and slitting.

The lab type film making machine can be used in pharmaceutical, cosmetic or food industry product manufacturing. If you want to produce patches, oral soluble film strips, mucosal adhesives, masks or any other coatings, our lab type film making machines always work reliably to achieve high precision coatings. Even complex products whose residual solvent levels must meet strict limits can be manufactured using our lab type film making machine.

This machine adopts the frequency converter to speed regulation,designed with intergrated automatic control of main machine,electricity, compressed air which strictly meet GMP standard and UL safety standard.

With its function of film making and drying, controlled by PLC panels,it is easy for running. all the technical support,and afterservices is available including commissioning in user site.

Performance & features

1. It is suitable for the composite production of paper and film coatings. The power system of the whole machine adopts servo drive speed regulation system. Unwinding adopts magnetic powder brake tension control.

2. The equipment has automatic working length record and speed display.

3. The drying oven adopts the heating method at the bottom of the flat plate, and the temperature is controlled by PID, and the control accuracy can reach ±3℃.

4. The rear transmission area and the front operation area of the equipment are completely sealed and isolated by stainless steel plates, which avoids cross-contamination between the two areas when the equipment is working, and is more convenient to clean.

5. All parts in contact with the material, including pressing rollers and drying tunnels, are made of stainless steel and non-toxic materials, in line with the requirements and specifications of “GMP”. All electrical components, wiring and operating schemes comply with “UL” safety standards.

6. The emergency stop safety device of the equipment improves the safety of operators during debugging and mold changing.

7. It has a one-stop assembly line of unwinding, coating, drying and winding, with smooth process and intuitive production process.

Main Technical Parameters

|

Item |

Parameter |

|

Effective production width |

120mm |

|

Roll width |

140mm |

|

Mechanical speed |

0.1-1.5m/min (Depends on actual material and status) |

|

Unwinding diameter |

≤φ150mm |

|

Rewinding diameter |

≤φ150mm |

|

Heating drying method |

Plate heating, centrifugal fan hot air exhaust |

|

Temperature control |

Room temperature: -100℃ ±3℃ |

|

Reel edge |

±3.0mm |

|

Total power |

5KW |

|

Dimensions |

1900*800*800mm |

|

Weight |

300Kg |

|

Voltage |

220V |

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for Low price for Emulsifier Mixer Machine - OZM-120 oral dissolving film making machine (lab type) – Aligned , The product will supply to all over the world, such as: Amsterdam, Sheffield, United States, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.