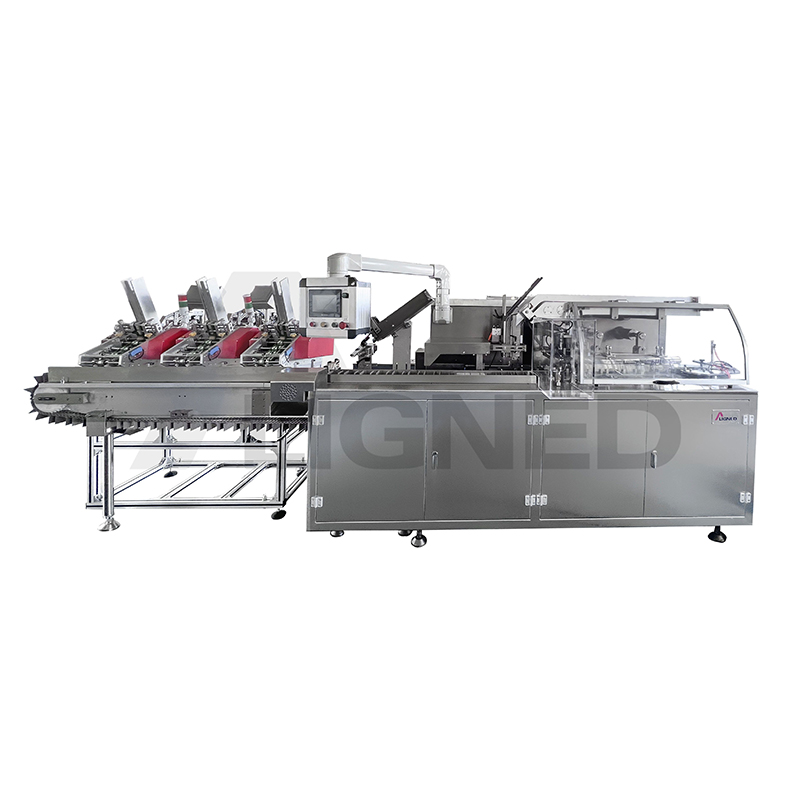

Leading Manufacturer for Transdermal Patch Making Machine - OZM-160 Automatic Oral Thin Film Making Machine – Aligned

Leading Manufacturer for Transdermal Patch Making Machine - OZM-160 Automatic Oral Thin Film Making Machine – Aligned Detail:

Features:

1. It is suitable for the coating compound production of paper, film and metal film. The power system of the whole machine adopts the servo drive speed regulation system. Unwinding adopts magnetic powder brake tension control.

2. It adopts the main body plus accessory module structure, and each module can be disassembled and installed separately. The installation is positioned by cylindrical pins and fastened by screws, which is easy to assemble.

3. The equipment has automatic working length record and speed display.

4. The drying oven is divided into independent partitions, with functions such as independent automatic control of temperature, humidity, and concentration to ensure efficient and high-quality production.

5. The lower transmission area and the upper operation area of the equipment are completely sealed and isolated by stainless steel plates, which avoids cross-contamination between the two areas when the equipment is working, and is easier to clean.

6. All parts in contact with materials, including pressure rollers and drying tunnels, are made of stainless steel and non-toxic materials, which meet the requirements and specifications of “GMP”. All electrical components, wiring and operating schemes comply with “UL” safety standards.

7. The emergency stop safety device of the equipment improves the safety of the operator during debugging and mold change.

8. It has a one-stop assembly line of unwinding, coating, drying and winding, with smooth process and intuitive production process.

9. The switchboard adopts a split structure, the drying area can be customized and lengthened, and the operation is smoother.

Technical Parameter

|

Item |

Parameters |

|

Effective production width |

140mm |

|

Roller surface width |

180mm |

|

Mechanical speed |

0.1-1.5m/min(Depends on actual material and status) |

|

Unwinding diameter |

≤φ200mm |

|

Rewinding diameter |

≤φ200mm |

|

Heating and drying method |

Built-in hot air drying, centrifugal fan hot air exhaust |

|

Temperature control |

Room temperature-100℃ ±3℃ |

|

Reel edge |

±3.0mm |

|

Total installed power |

18KW |

|

Dimensions |

3470*1280*2150mm |

|

Voltage |

380V |

Equipment details

Film making area

1. Independent film-making head, which can realize 3-axis direction adjustment;

2. The main roller is controlled by a servo motor to adjust the speed of the main machine.

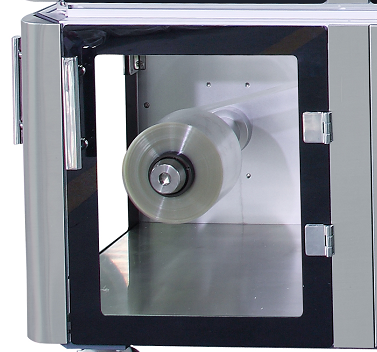

Unwind area

1. The unwinding device adopts the air shaft main roller;

2. Unwinding tension is adjusted by magnetic powder clutch;

3. Lack of foil alarm.

Dry area

1. The oven has a built-in hot air high-efficiency filter to realize no-cleaning of the internal pipeline, and is equipped with pressure difference protection inside the oven to facilitate regular replacement of the high-efficiency filter;

2. Temperature and humidity control inside the oven;

3. The oven is made of all stainless steel, and the opening and closing of the oven are controlled by the cylinder.

Winding area

1. The winding device adopts servo motor to control the winding speed;

2. The film winding is equipped with a speedometer to monitor the film conveying speed in real time.

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Leading Manufacturer for Transdermal Patch Making Machine - OZM-160 Automatic Oral Thin Film Making Machine – Aligned , The product will supply to all over the world, such as: Nepal, Chile, Swedish, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!