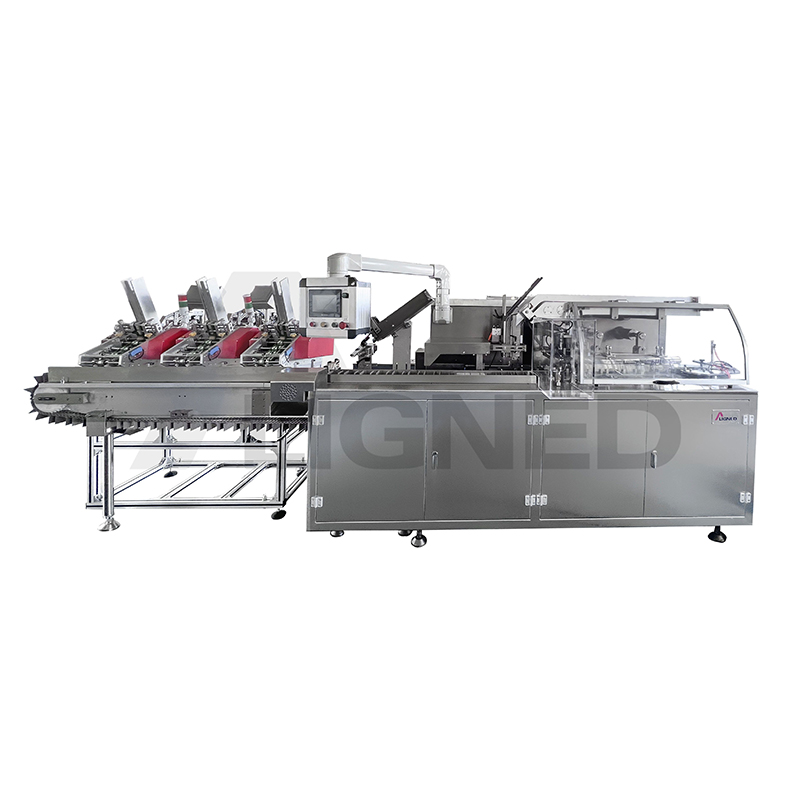

KXH-130 Automatic Sachet Cartoning machine

Product Video

Sample diagram

Work Process

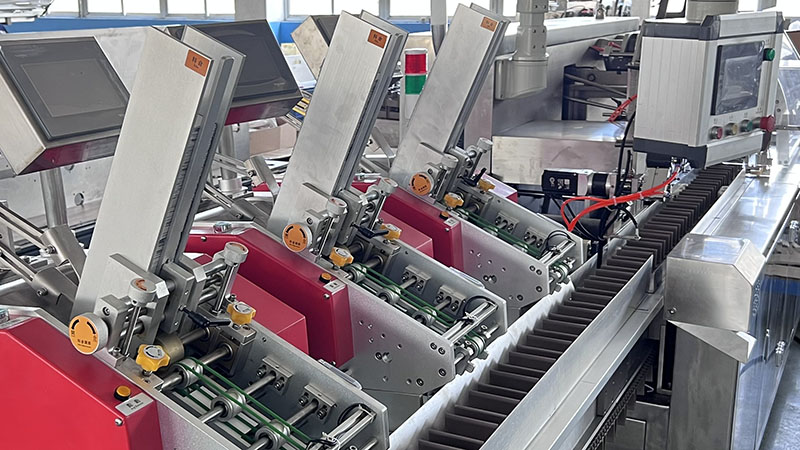

● Product loading

● Vertical sachets transfer

● Flat blank magazine and pickup

● Carton erection

● Product pusher

● Side flap closing

● Flap tuck in operation

● Carton closure/End Hot spraying

● Code embossing

● Code Steel stamping

● Carton discharge

Features

1. Integrated cartoning machine designed for sachet packaging.

2. The packing quantity is adjustable, 5, 10 or 30 pieces per box, other quantities can be customized.

3. Tooless carton changeover.

4. Complete automatic code embossing print and stamping both ends of carton.

5. Adopts an independent PLC with advanced touch screen HMI, while the electrical systems are mainly Siemens, SMC.

6. All moving parts and actuating device are operated with an auto stop mechanism using a safety cover.

7. Optimized working efficiency at every stage in the carton packaging process.

8. Product presence sensor (no product, no carton).

9. Advanced and compact construction design in GMP Compliance.

10. Highest flexibility with highly dynamic servo drives.

11. Easy and clearly organized machine operation.

12. Presence with glue closing option.

Technical Parameter

|

Items |

Parameters |

|

|

Cartoning Speed |

80-120 boxes/min |

|

|

Box |

Quality Requirement |

250-350g/㎡[ Base on carton size ] |

|

Dimension Range (L×W×H) |

(70-180)mm × (35-80)mm × (15-50)mm |

|

|

Leaflet |

Quality Requirement |

60-70g/㎡ |

|

Unfolded Leaflet Specification (L×W) |

(80-250)mm ×(90-170)mm |

|

|

Fold Range (L×W) |

[ 1-4 ] Fold |

|

|

Compressed Air |

Working Pressure |

≥0.6mpa |

|

Air Consumption |

120-160 L/min |

|

|

Power Supply |

220V 50HZ |

|

|

Main Motor Power |

1.1kw |

|

|

Machine Dimension(L×W×H) |

3100mm × 1100mm × 1550mm (Around) |

|

|

Machine Weight |

Around 1400kg |

|