KFM-300H High Speed Oral Disintegrating Film Packaging Machine

Sample diagram

Device Description

Aligned KFM-300H High Speed Oral Disintegrating Film Packaging Machine is designed for cutting, integrating, compounding, and sealing film-like materials, catering to pharmaceutical, healthcare, food, and other industries.

Oral dissolving Film Packaging Machine features variable frequency speed regulation technology and an automatic control system that integrates machinery, electricity, light, and gas for precise adjustments according to production requirements. This ensures improved stability, reliability, and smooth operation, while simplifying equipment operation and reducing production debugging complexity.

Packaging machine developed for oral dissolving film adhering to GMP and UL safety standards, the design and manufacturing processes prioritize operator safety and finished product quality.

This machine boasts a sleek and easy-to-clean appearance design, with functions such as pre-slitting, slitting, heat sealing, and cutting accurately controlled via the control panel, thereby improving the production efficiency and product quality of Oral Thin Film (OTF).

Features

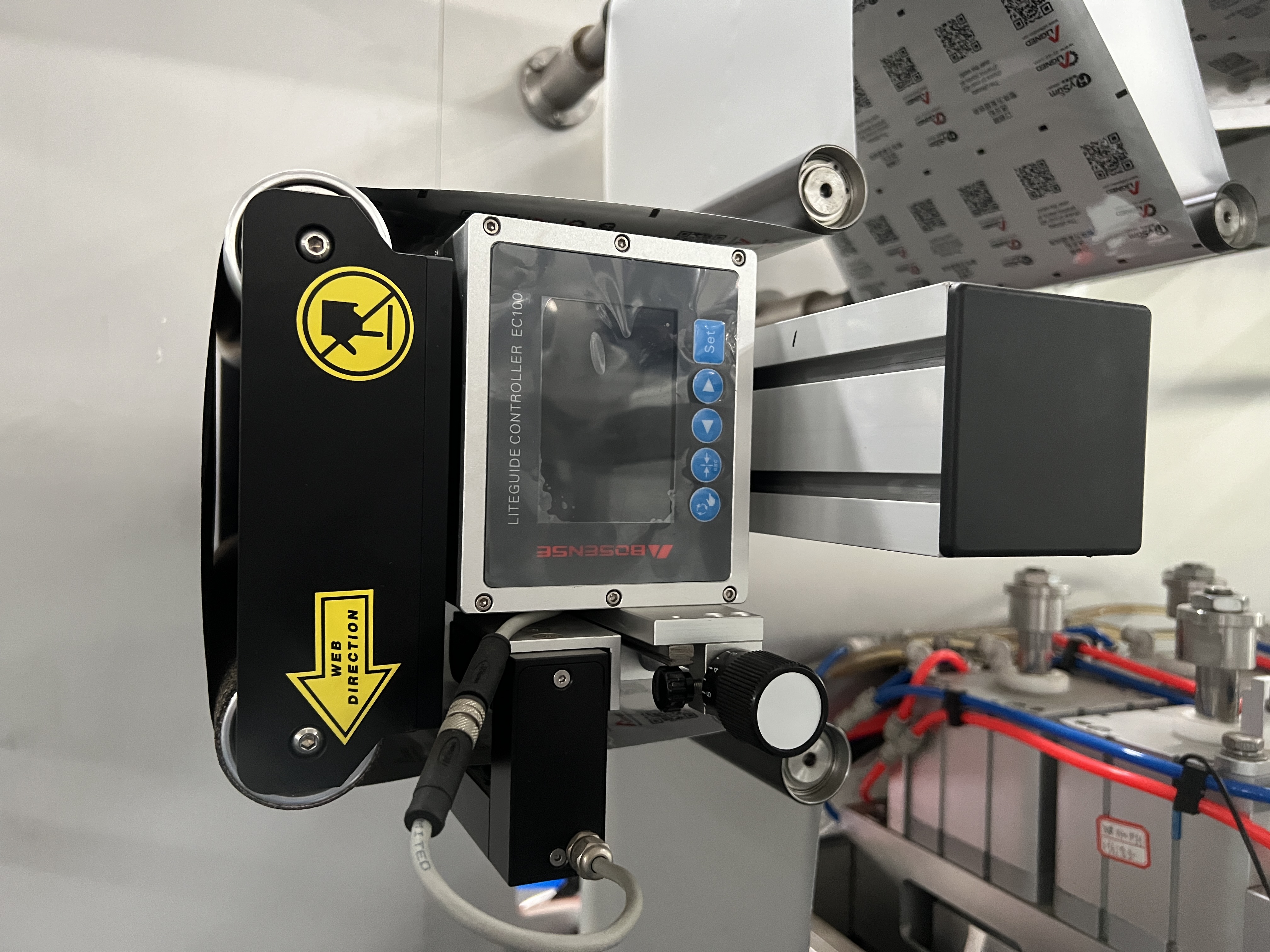

1.The automatic correction of the unwinding shaft for mouth-dissolving film materials provides an adjustment space of 20-30mm. Additionally, the upper and lower film packaging positions are equipped with correction devices, totaling 3 correction devices in the entire machine, enhancing the accuracy of heat sealing for packaging materials and film materials.

2.The new high-speed packaging machine can stably produce 1200 packs per minute, which is six times that of the old model.

3.The waste roll device has been upgraded to include crushing and dust suction functions, facilitating the collection of waste materials, saving storage space, and maintaining equipment cleanliness.

4.Double-sided registration is included as standard, enriching the packaging printing content, showcasing different brand elements and visual identification symbols, thereby improving recognition and memorability.

5.Visual inspection of mouth-dissolving film material is included as standard, detecting issues such as edge rolling, missing parts, and damage, thereby enhancing product quality.

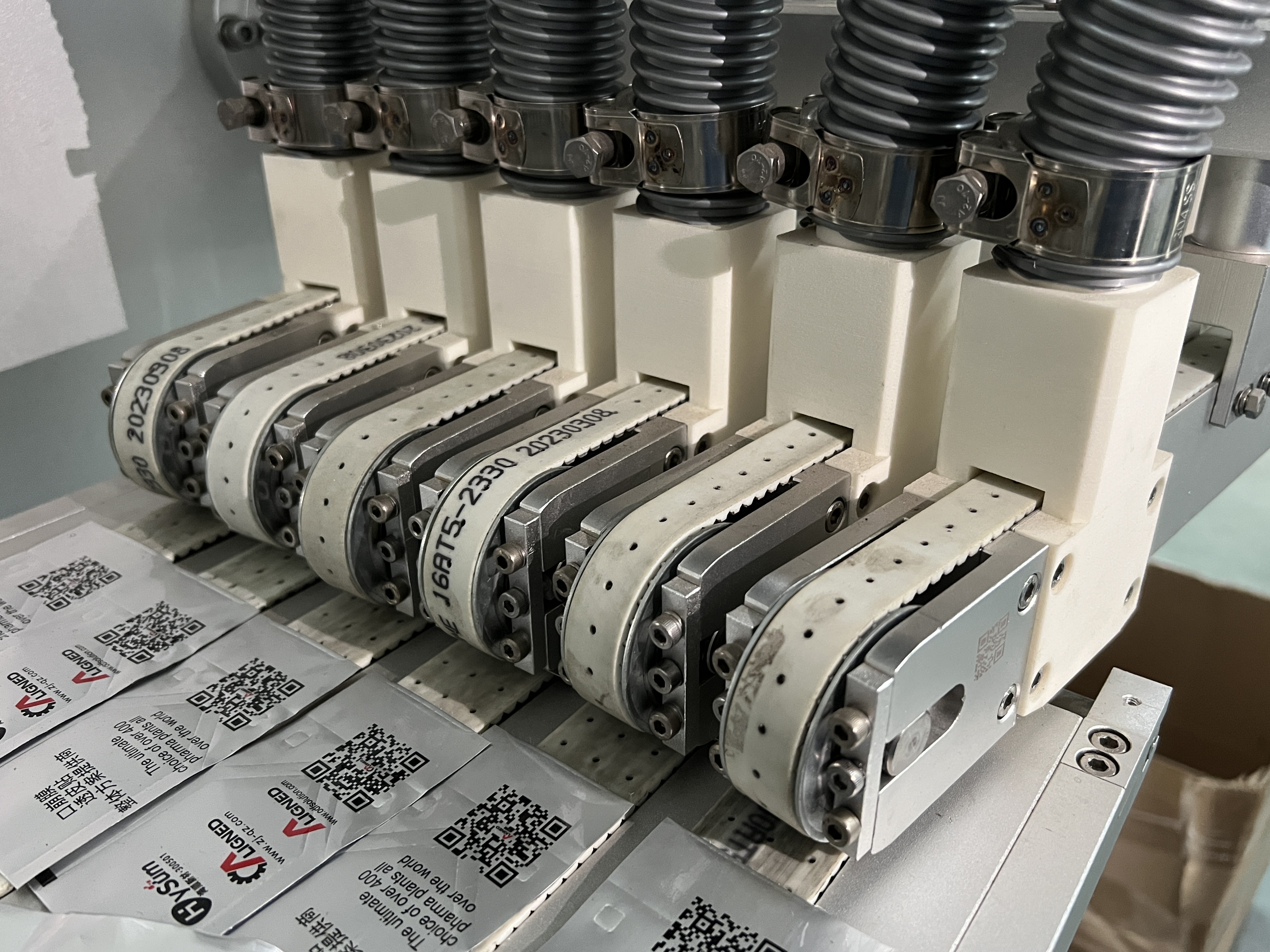

6.The heat sealing device operates in a reciprocating motion at 35 times per minute, with each mold containing 36 packs, thus increasing production output.

7.The upgraded finished product conveyor belt is vacuum adsorption type, equipped with pneumatic reject device, effectively eliminating defective products and heat sealing rejects.

Work Process

Packaging Film Feeding System:

Consists of an external double-sided film dispensing mechanism and upper and lower packaging film deflection transfer mechanism.

All film roll supply is servo-controlled, ensuring automatic supply according to production needs.

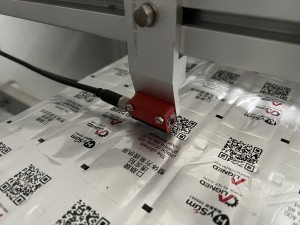

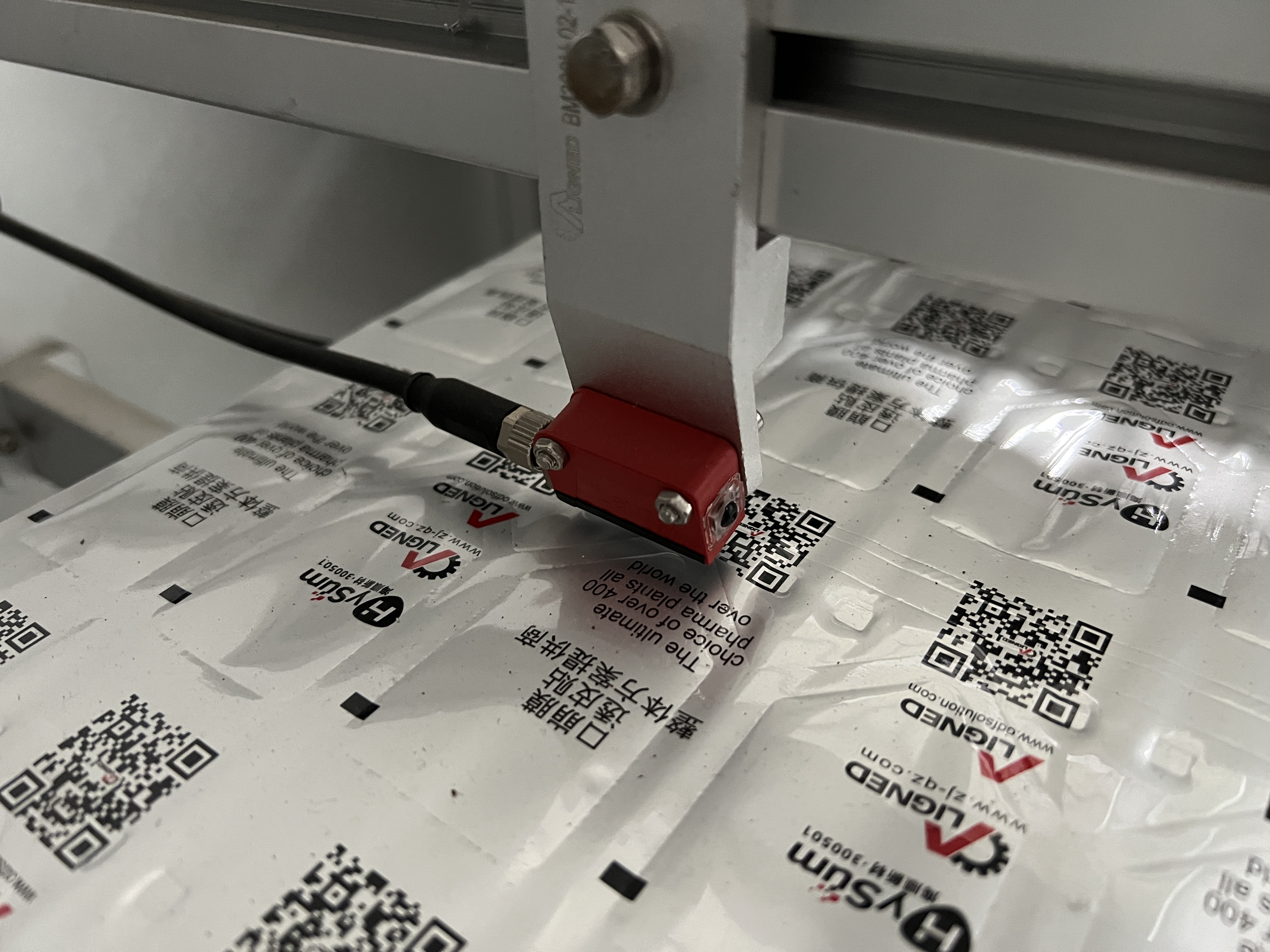

The double-faced plate mechanism features a cursor alignment function for precise heat sealing position correspondence between upper and lower packaging materials.

Side adjustment mechanism allows fine-tuning of front and rear positions.

Orally Disintegrating Film Tablet Processing System:

Comprises material unwinding station, material cutting station, and material peeling mechanism.

Orally disintegrating film is unrolled under servo control with a buffer swing bar ensuring stable supply speed and buffer space.

Cutting station cuts material film to required width and removes waste edge structure.

Strip peeling mechanism adopts layout, pre-cutting, and peeling design, cutting material film into specified length film pieces, peeled off from bottom film, and accurately placed on packaging film for subsequent processes.

Reciprocating Heat Sealing System:

Servo motion control adjusts heat sealing speed accurately according to production requirements. Heat sealing temperature is controllable to ensure stable sealing effect.

Finished Product Packaging Cutting System:

Heat-sealed finished product is cut to required size by cross-cutting and longitudinal-cutting mechanisms.

Finished product output port equipped with negative pressure adsorption and conveying mechanism, along with pneumatic waste removal device to effectively remove waste and defective products.

Technical Parameter

|

Parameter |

Specification |

|

Equipment Model |

KFM-300H |

|

Heat Sealing |

Six columns and six packets, standard heat sealing of 36 packets per sheet |

|

Cutting and Heat Sealing Speed |

10-35 times/minute |

|

Film Width |

Coordinated with double-sided registration mechanism, total width of single roll film is 520mm |

|

Unwinding Diameter |

≤φ200mm |

|

Rewinding Diameter |

≤φ200mm |

|

Total Installed Power |

36Kw |

|

Dimensions |

Main Unit686012502110 mm Double-sided Registration Mechanism 130012391970 mm |

|

Weight |

7000Kg |

|

Voltage |

380V |