KFM-230 Automatic Oral thin film Packaging machine

Product Video

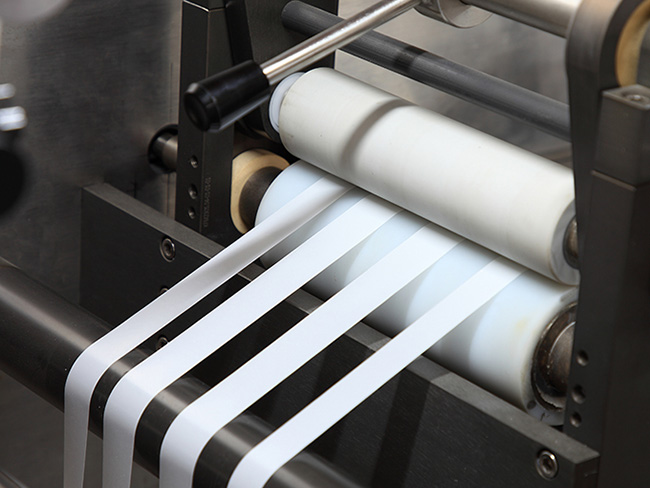

Sample diagram

Application

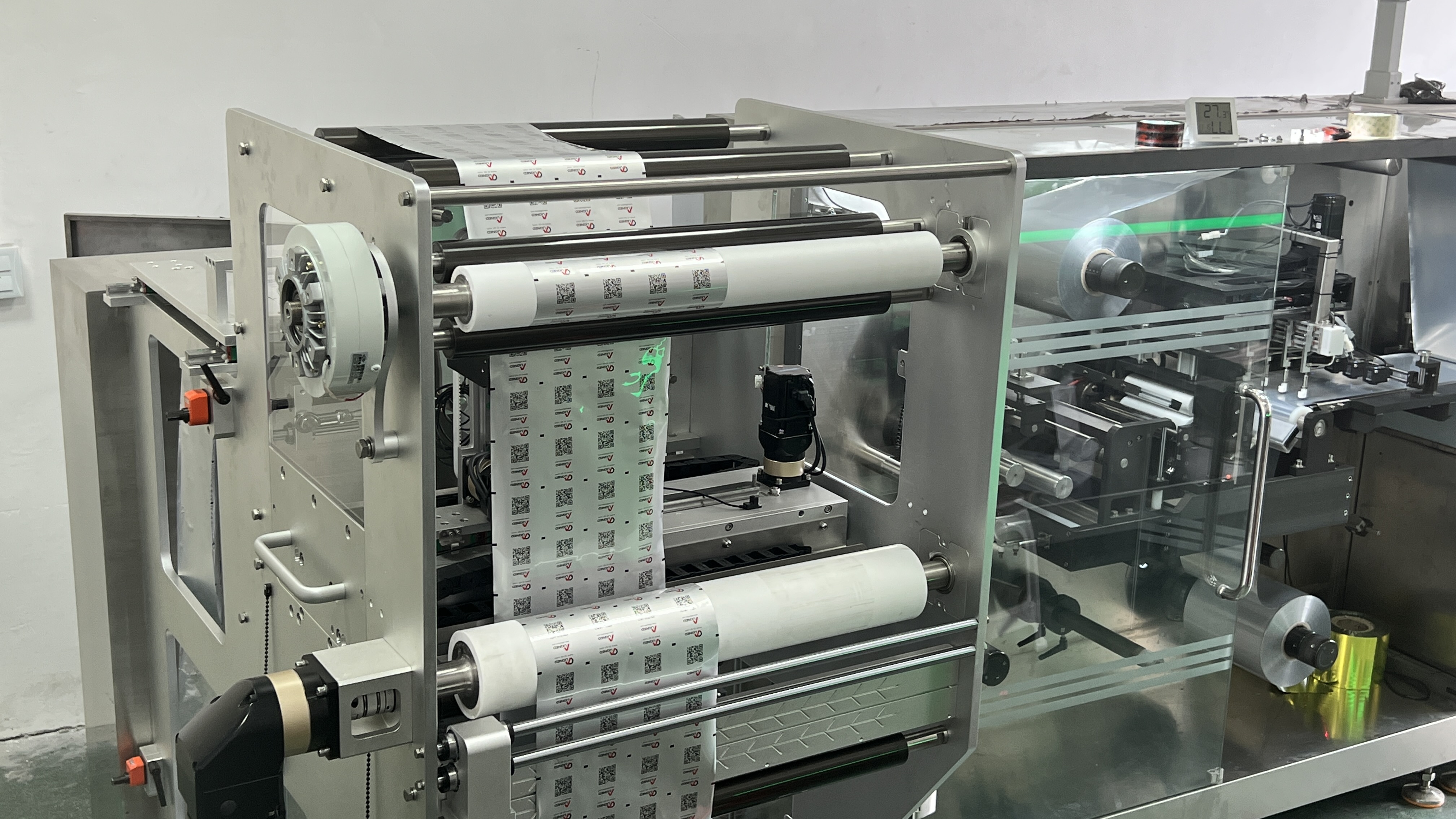

●This machine cutting and crosscutting inter across the integration, the material can be precisely divided into a single sheet-like products, and then use the sucker to accurately locate and move the material to the packaging film, laminated, heat sealing, punching, the final output Packaging complete product, to achieve the integration of the product line packaging.

●The main motor using frequency control, according to the length of the trip and the size of the product to set the corresponding number of blanking.

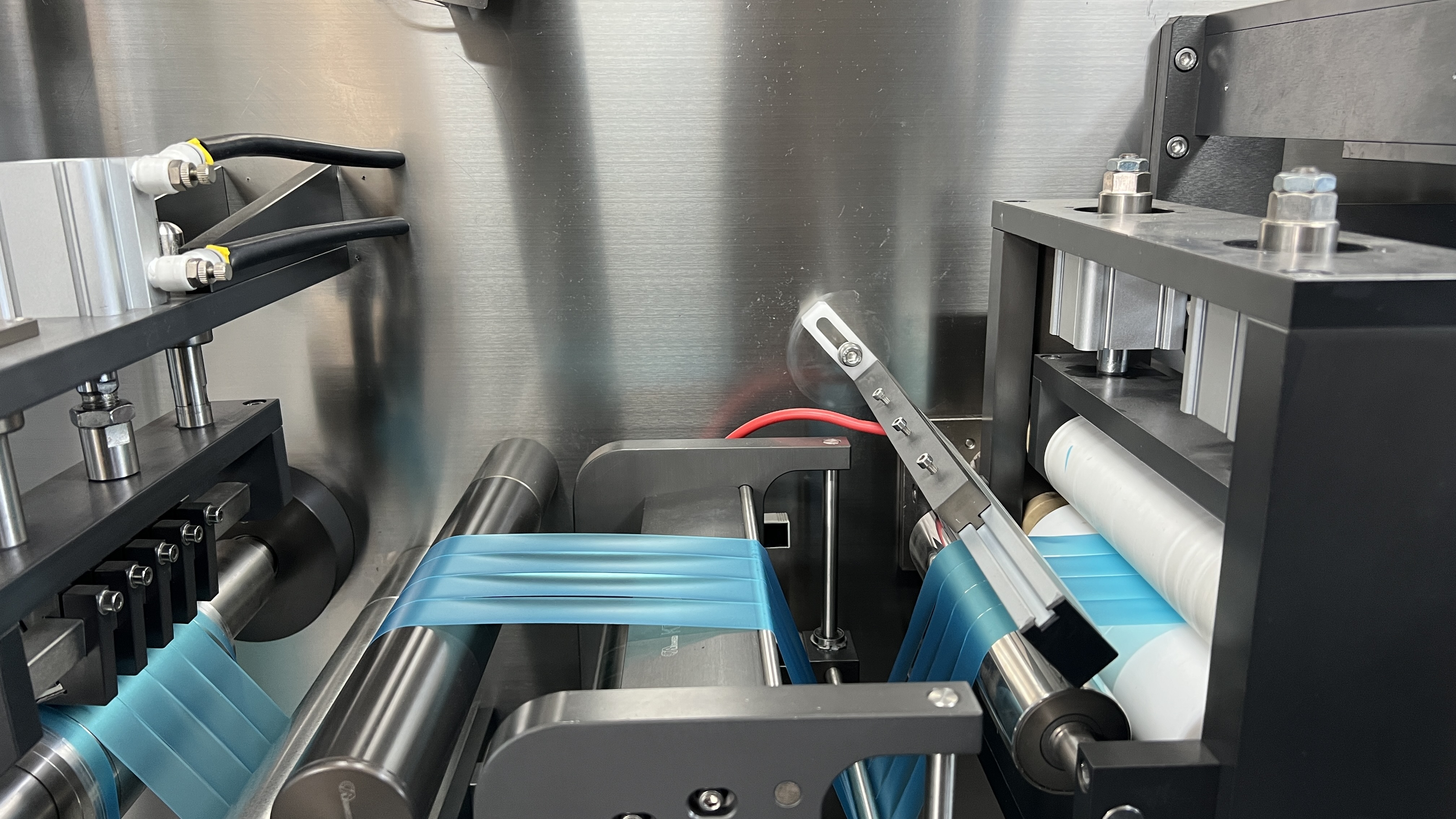

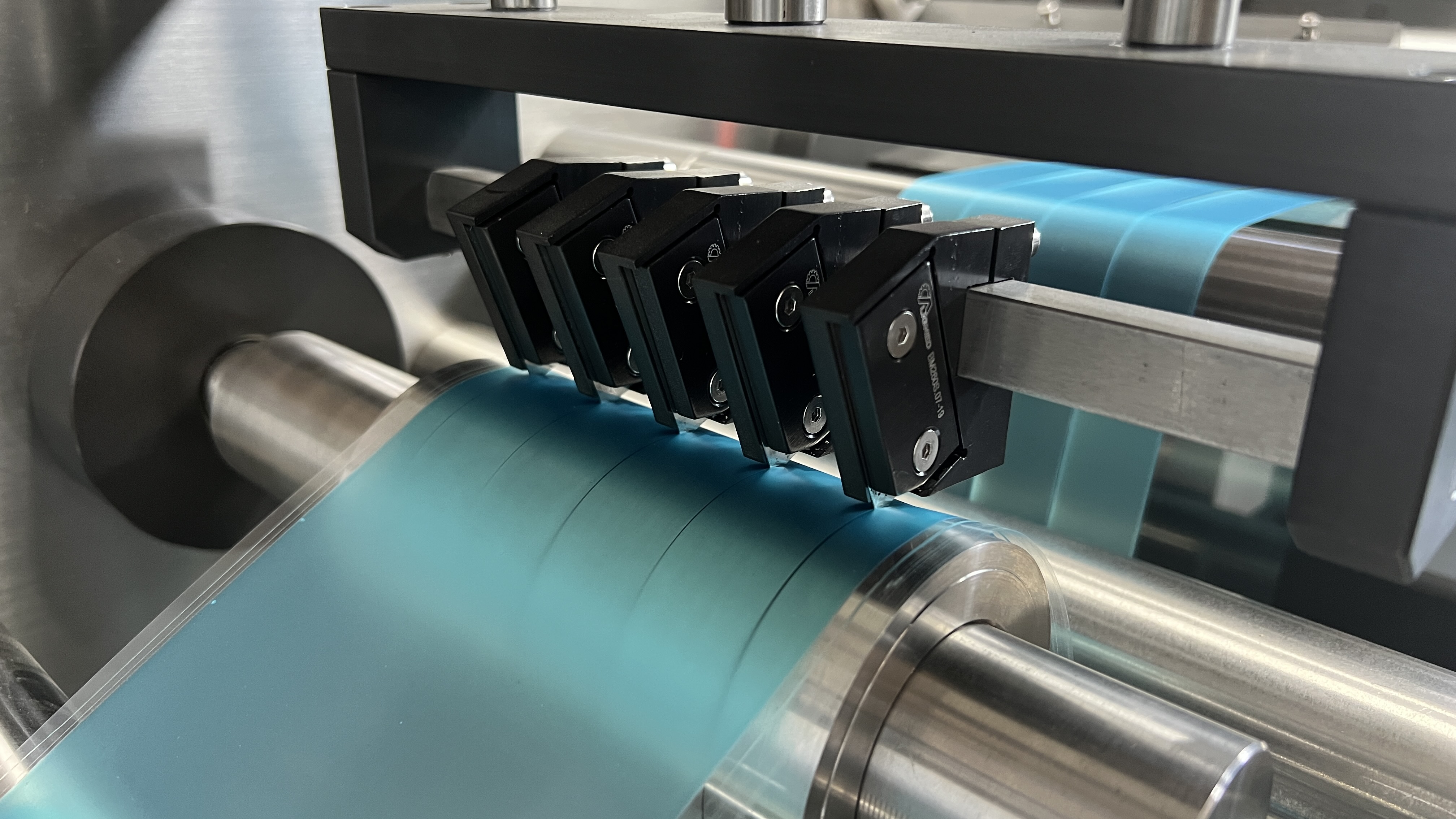

●Using manipulator holds the traction mechanism, smooth operation, accurate synchronization, in the range can be arbitrarily designed plate size. Due to the use of contact-type version of the heating, reducing the heating power and temperature, save energy and increase the stability of plastic.

●After the use of packaging materials, pinch automatically alarm, stop, and equipped with emergency stop safety device to improve the operator in the debugging and mold for the safety.

●All parts in contact with the material and other parts, are made of stainless steel and non-toxic materials, meet the "GMP" requirements.

●The machine is ideal for packing film strips into pouch, such as oral dissolving films, mint strips, adhesive patch, etc, having advantages of safe take-away medicine, easy to apply, handle and store, dampness proof, perfect sealing design, strong shading, flexible bag design in shape, size and color.

●Equipped with a deviation correction device to prevent materials from deflecting during movement.

●Equipped with a tension sensor to adjust the tightening tension according to the diameter of the reel.

●Optional double-sided printing function allows the front and back of each piece of packaging to be correctly and automatically aligned, enhancing the richness of packaging content.

Performance and Features

A. This machine uses split module construction.

During transport and cleaning, the module can be removed separately for easy operation.

B. The main motor using frequency control, according to the length of the trip and the size of the product to set the corresponding number of blanking.

C. Adopts manipulator holding the traction mechanism, smooth operation, accurate synchronization, in the range of any adjustable, that is: strip size could be designed in the range arbitrarily.

D. All parts in contact with the material are made of stainless steel and non-toxic materials and meet "GMP" requirements.

E. Slitting and crosscutting integrated, the material can be precisely divided into a single sheet-like products, and then use the sucker to accurately locate and move the material to the packaging film, laminated, heat sealing, punching, and then output, whole process achieves the integration of product line packaging.

Main Technical Parameters

| Items | Parameter | |

| Maximum punching speed (standard 45 x 70 x 0.1mm) | AL foil 5-40 times / min | |

| Packing Film Width | 200-260 mm | |

| Materials Width | 100-140 mm | |

| Heat sealing heating power | 1.5KW | |

| Power and total power | Three-phase five lines 380V50/60HZ, 5.8KW | |

| main motor power | 1.5KW | |

| Air pump volume flow | >0.25m3/min | |

| Packing Material | Heat-seal composite film thickness 0.03-0.05m | |

| Overall dimensions(L*W*H) | 3400X920X2000mm | |

| Machine package size(L*W*H) | 3420X1080X2200mm | |

| Total Weight | 2400Kg | |