Excellent quality Automatic Cellophane Packing Machine - OZM-340-4M Automatic Oral thin film making machine – Aligned

Excellent quality Automatic Cellophane Packing Machine - OZM-340-4M Automatic Oral thin film making machine – Aligned Detail:

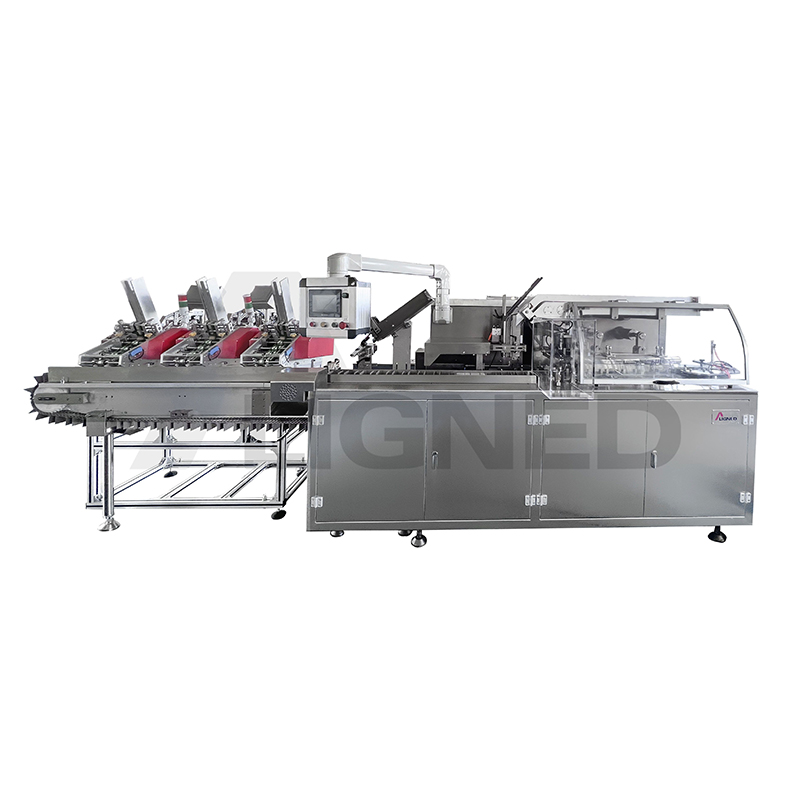

Sample diagram

Features

High dosing accuracy, quick dissolving,fast release, no swallowing difficulty, high acceptance by elderly and children, small size convenient to carry.

Working principle

The working principle of the machine is evenly coated a layer of liquid material on the surface of the reel base roll. The solvent (moisture) is rapidly evaporated and dried through drying channel. And winding up after cooling (or composite with another material). Then, get the final products of the film (composite film).

Performance & features

These equipment adopts frequency conversion speed control and automatic control technology of machine, electric, light and gas, and innovates the design according to the “GMP” standard and the “UL” Safety Standard of the pharmaceutical industry. The Film Making Machine has the functions of film making, air drying and other features. All the data parameters are regulated by the PLC control panel. The model is for the new thin film drugs for continuous improvement, innovation and research and development, its comprehensive performance to the leading domestic level, the technology to fill the gaps, and imported equipment more practical and economical.

Main Technical Parameters

| Items | Parameters |

| Model | OZM-340II |

| Max casting width | 360mm |

| Roll width of film | 400mm |

| Running Speed | 0.1m-1.5m/min (depends on formula and process technology) |

| Unwinding diameter | ≤φ350mm |

| Winding diameter | ≤350mm |

| Method of heat & dry | Heating by external stainless steel heater, hot air circulation in centrifugal fan |

| Temperature control | 30~80℃±2℃ |

| Edge of reeling | ±3.0mm |

| Power | 16Kw |

| Overall dimension | L×W×H: 2980*1540*1900mm |

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for Excellent quality Automatic Cellophane Packing Machine - OZM-340-4M Automatic Oral thin film making machine – Aligned , The product will supply to all over the world, such as: belarus, Hamburg, Argentina, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.